51 years of magazine history here.

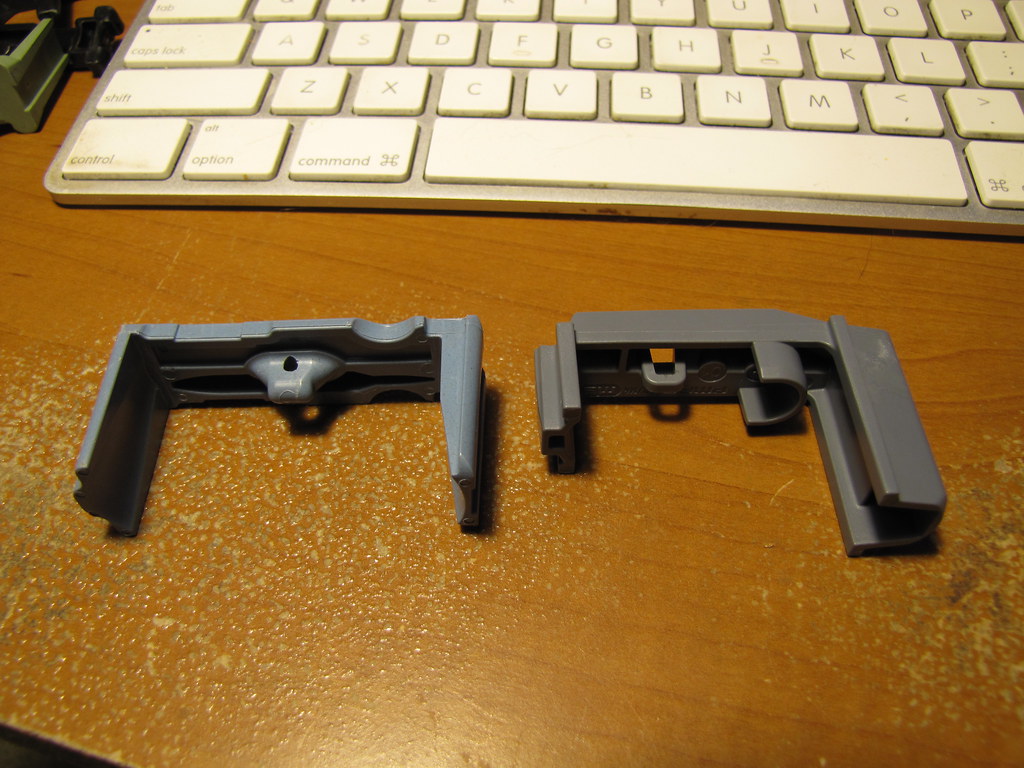

Left to Right:

Colt p/n 62667 gray aluminum body, emerald green 62665A follower

NSN 1005-00-921-5004 gray aluminum body, black follower

NSN 1005-00-921-5004 gray aluminum body, light green follower

NSN 1005-00-561-7200 gray aluminum body, tan follower

NSN 1005-01-615-5169 black, windowed PMAG-30 M3

NSN 1005-01-630-9508 tan aluminum body, sky-blue follower

NSN 1005-01-659-7086 medium coyote tan, windowed PMAG-30 M3

As you can see, the Colt design from 1967 is really still in service.

The original has a plain steel spring and a very dark green follower.

|

| 62665A follower on left. |

|

| It's stamped with Colt's part number. |

The first 30-rounder to rate a

National NATO Stock Number (NSN), in 1972, is very much the same magazine as the Colt 62667. The coating changes from a plain, clear anodizing to a light-gray anodizing with a dry-film lubricant both inside and out.

The, now black, follower is virtually identical to the dark green Colt.

|

| NSN 1005-00-921-5004 on right. |

The spring was changed from plain steel to a coated/plated steel:

|

| Colt on left, black-follower on right. |

Desert Storm showed there was something wrong with our magazines. There are several theories as to what exactly was the reason for failure, but the Army decided that it was because the black follower allowed too much tilt and that allowed it to bind up inside the magazine.

So the light green follower was issued under the same NSN.

Service in Iraq and Afghanistan show that the green follower wasn't fully solving the problem.

A teeny start-up in Colorado, Magpul, adds a product to their line-up in 2004. A replacement follower that fits in a standard USGI 30-rounder and uses the standard spring. It's use is both banned or grudgingly accepted (sometimes both) depending on unit and commands.

Magpul enters the magazine market in 2007. Their original PMAG was marketed as a cheap, training magazine and not sold as a "bet your life on it" service magazine. Many of them find their way into Soldier's and Marines' ammo pouches. The troops appear to love them. Several models of PMAG are given an NSN, but none are actually considered issue. The NSN simply allows unit funds to make purchases without breaking regulations. Despite the sanctifying NSN, the use of Magpul's baby is banned more than once by various levels of command, and these bans are rescinded several times as well.

The popularity of the plastic magazines from Magpul and a strong feeling of "Not Invented Here!" along with noting that the Self-Leveling-Followers appeared to fix the problems with 1005-00-921-5004 causes the Army to adopt NSN 1005-00-561-7200 in 2009.

The big change is a tan follower with stronger anti-tilt features.

|

| They changed which side the stagger starts on too. |

The new tan follower has a very strong resemblance to Magpul's...

The spring is also changed because it goes through the follower nearer the center.

|

| Light Green on left, Tan on right. |

Magpul keeps updating and upgrading their PMAG as well, resulting in the Gen M3 in 2013. This magazine, depending on color and features, is also issued an NSN.

Citing problems with the new M855A1 ammunition's steel tip striking the aluminum lower portion of the feed ramps, yet another change to the magazine is made in 2016, given NSN 1005-01-630-9508 and dubbed the "Enhanced Performance Magazine" or EPM.

The body changes color from an anodized gray to a painted tan. It appears, to me, that this paint is applied over the top of gray anodizing... The mouth of the magazine is altered slightly to present the noses of the rounds slightly higher so they miss the aluminum below the steel barrel extension.

The follower appears to be the same as before, but now in sky-blue.

The EPM did not prove to be the panacea it was hoped to be. Some troops complained it didn't really work any better than the old tan-follower mags, it was just easier on the guns.

Several sources noted that the new feed angle was identical to what Magpul had been using since 2007! Magpul's goal was similar, avoid hitting the aluminum below the barrel extension; but for a different reason. The M4 carbine had introduced extended feed ramps that went down into the aluminum of the upper receiver because the bolt-speed of the M4 was causing the noses of the rounds to hit the front of the receiver. Magpul was trying to make a reliable magazine for a market which had not fully embraced the so-called M4 feed ramp.

The EPM caused problems in particular with the Marines' M27 IAR.

So they adopted the PMAG Gen M3, with maglevel window, in both black and medium coyote tan using NSN 1005-01-615-5169 and 1005-01-659-7086 respectively. They reportedly would have been happy to keep using the green or tan follower magazines, but orders made under those NSN's would start receiving EPM magazines as soon as stocks of the older magazines had been depleted.

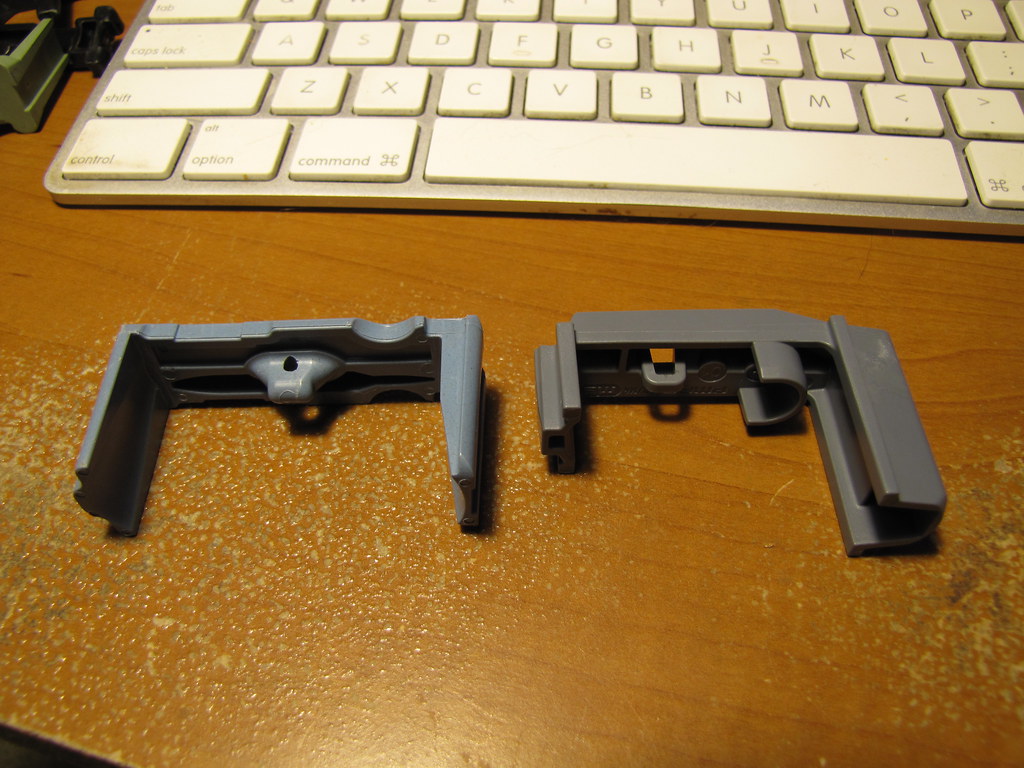

The PMAG uses the same spring as the old NSN 1005-00-921-5004 and its follower has no relation to any aluminum body magazine.

|

| EPM on left, Gen M3 on right. |

This is because the PMAG doesn't have a curved to straight transition inside, it's a constant curve the entire length. Colt tried to do a constant curve as early as 1965 but was confounded by their own sloppy dimensional tolerances in the M16's magazine well.

At the time of this writing, it appears that The Army might even be considering following in the USMC's footsteps and adopting the PMAG. Stay tuned!